MR62 (AMS) is a Type II solvent removable red colour penetrant ideal for general industrial dye penetrant testing. It exhibits outstanding penetrating characteristics along with vivid classic red indications which provides maximum reliability in locating surface open flaws and discontinuities. Typical application include casting, forgings, leak testing, welds, pressure vessels and general metal works.

2511-0003_Guest

- INR

- ZAR

Main Menu

MR62 (AMS), Penetrant - Red; Solvent Removable

Product Information

MR62 (AMS) is a Type II solvent removable red colour penetrant ideal for general industrial dye penetrant testing. It exhibits outstanding penetrating characteristics along with vivid classic red indications which provides maximum reliability in locating surface open flaws and discontinuities. Typical application include casting, forgings, leak testing, welds, pressure vessels and general metal works.

| # | Attribute | Value |

|---|---|---|

| 1. | brand | MR Chemie |

- Vivid classic red, clear indications under white light

- Free of aromatics, oil-based

- Superior reliability

- NPE-free

- Phthalate-free

- Superior surface wetting

- Low odour

- Outstanding penetrating capability

- Instant indications � high capillary action

- Easy to apply and easy to clean

- Low toxicity

- Suitable for all metals (suitability for plastics & ceramics requires testing prior to use)

| PROPERTIES | |

|---|---|

| APPROVALS | |

| FAMILY TESTING | Penetrant – MR62 |

| RECOMMENDED USAGE | NDT Method – Dye Penetrant Testing |

| REFERENCE TEST BLOCKS | Reference test block type 1 (Ni-Cr panel – 30µm & 50µm) |

How it Works

Penetrants in NDT work by taking advantage of the capillary action principle, which is the ability of a liquid to flow into narrow spaces without the assistance of, or even in opposition to, external forces like gravity.

The penetrant used in NDT is a liquid that is applied to the surface of the material being inspected and allowed to seep into surface-breaking defects, such as cracks or porosity. After a certain amount of time, the excess penetrant is wiped off the surface, leaving only the penetrant that has seeped into the defects. A developer is then applied to the surface, which draws the trapped penetrant out of the defects, making them visible to the naked eye. The developer also amplifies the penetrant’s fluorescence, making the defects visible under UV light.

The penetrant works by using a combination of capillary action, surface tension, and viscosity to penetrate the surface-breaking defects. The penetrant liquid contains a dye or fluorescent material that allows the defects to be seen under white or UV light, respectively.

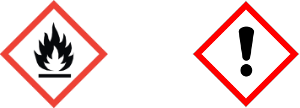

GHS

Aerosol

UN Model Regulation – UN 1950 AEROSOLS, 2.1

Bulk

Non Hazardous

A: Penetrant testing, also known as dye penetrant inspection, is a non-destructive testing (NDT) technique used to detect surface-breaking defects such as cracks, porosity, laps, and seams on the surface of solid materials.

A: Penetrant testing works by applying a liquid dye penetrant to the surface of a material. The penetrant flows into any surface defects and is allowed to soak for a specified time. Excess penetrant is then removed, and a developer is applied, which draws the penetrant out of the defects and makes them visible.

A: Penetrant testing is a relatively simple and cost-effective method for detecting surface defects on a wide range of materials. It can be used on a variety of surface geometries, including complex shapes, and is capable of detecting very small defects.

A: Penetrant testing is only capable of detecting surface-breaking defects and is not effective for detecting subsurface defects. It also requires a clean and dry surface to be effective and may not be suitable for use on certain materials, such as porous materials.

A: There are three types of penetrant testing: Type I (Fluorescent), Type II (Visible), and Type III (Visible & Fluorescent). Each type uses a different type of penetrant and developer and has different application and removal procedures.

A: Penetrant testing is commonly used in industries such as aerospace, automotive, and manufacturing to detect surface defects in materials such as metal, plastic, and ceramic components. It is also used in the inspection of welds, castings, and forgings.

A: The typical sensitivity of a visible penetrant is Level 2; as dictated by the EN-ISO 3452-2 standard.

A: The typical sensitivity classes of a fluorescent penetrant are Level 0.5, Level 1, Level 2, Level 3 & Level 4; as dictated by the EN-ISO 3452-2 standard.

A: Type testing

When seeking approval for a penetrant in accordance with material specifications such as AMS 2644 and EN ISO 3452-2, the penetrant manufacturer is responsible for getting the product Type tested. This involves sending a sample of the penetrant off to an independent laboratory for verification against a comprehensive set of standard tests.

Batch testing

During the routine manufacture of a penetrant and its associated consumable products, it is a requirement under material specifications such as AMS 2644 and EN ISO 3452-2 to carry out a number of batch-specific tests, including flash point, viscosity and fluorescent brightness (Type 1 systems only). These specifications also specify the sampling rate and dictate that we should publish these results on a certificate of conformance. For MR Chemie penetrants, cleaners, developers and emulsifiers, these certificates of conformance are referred to as Batch Inspection Certificates (or) Test Certificates

In-use testing

When a penetrant is being used, there are a set of in-use tests that need to be carried out by the customer. ASTM E1417 has established standards for performance checks for in-use materials

A: The sensitivity of a penetrant is not just simply its ability to find different sized cracks/defects; it also relates to aspects such as the type of surface finish. For example, on a rough casting you would not want to use a high sensitivity penetrant as it would be too difficult to remove, and you would see a lot of penetrant in the background. Conversely, on a highly polished part you would not want to use a low sensitivity penetrant as the risk of over washing and removing penetrant from the cracks/defects would be high. The sensitivity of a penetrant is ultimately determined by the independent laboratories that assess the penetrant in accordance with material specifications such as AMS 2644 and EN-ISO 3452-2.